ENVIRONMENTAL IMPACT

Stringent emissions and efficiency requirements govern the operations of the waste-to-energy plant. The plant, which handles a maximum of 135,000 tonnes of waste each year, is the primary solution for meeting all the district heating needs of the city of Salo, as almost 90% of the demand can be met by energy from waste.

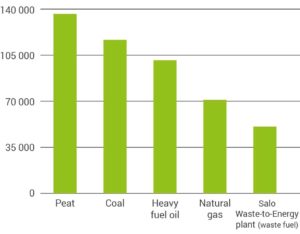

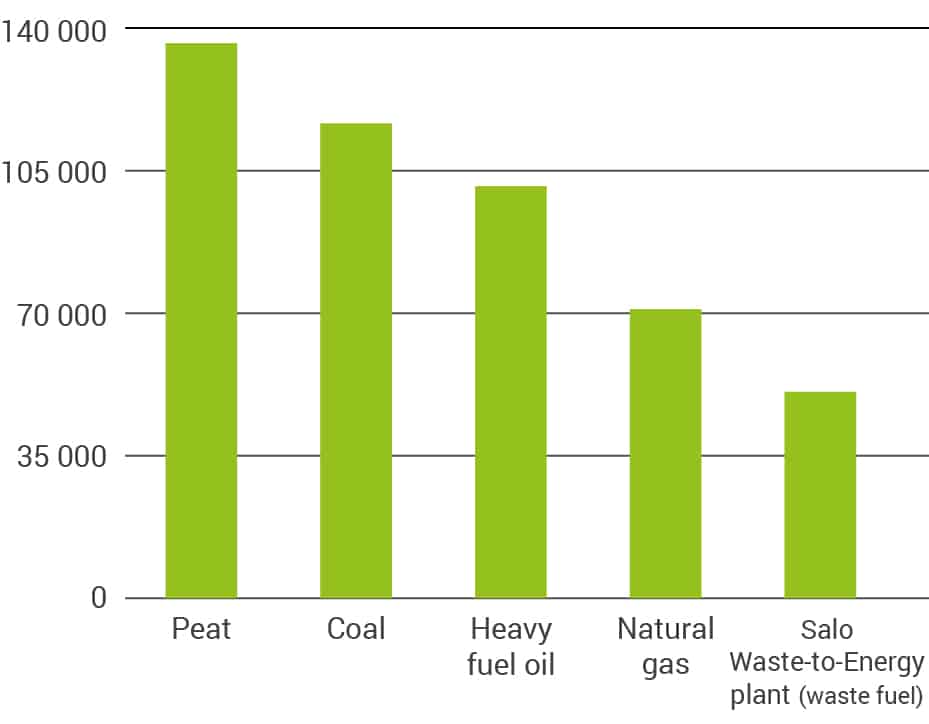

The WtE plant replaced fossil fuels and peat in primary energy production. The WtE plant halved emissions in district heating in Salo, as the impact of the plant is lower than that of power plants running on peat, coal or oil.

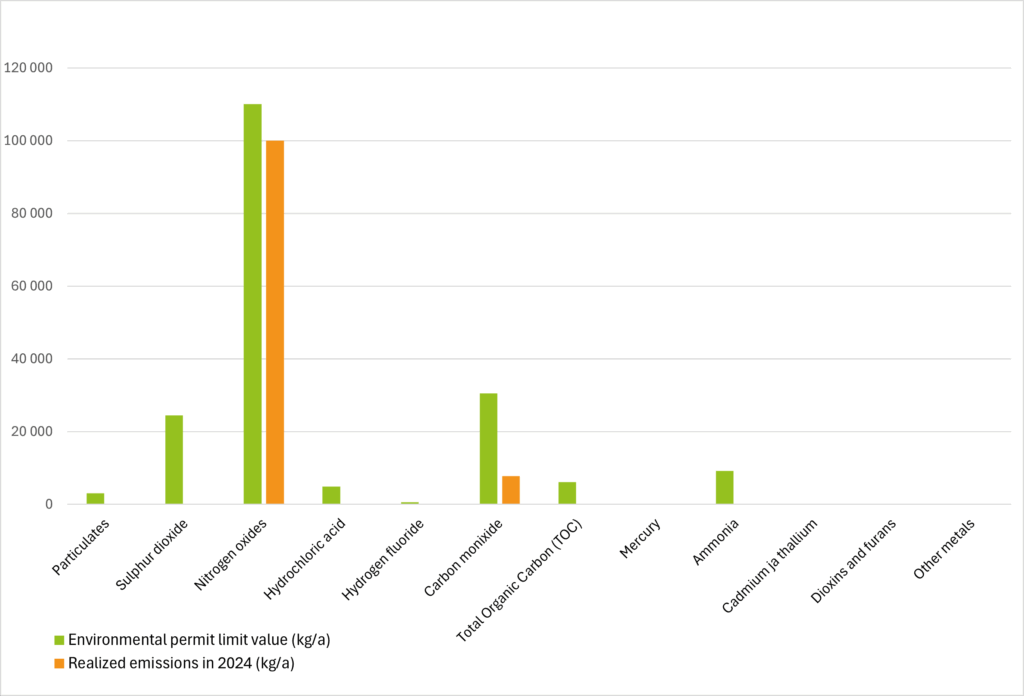

Emissions in line with the environmental permit

The waste-to-energy plant is equipped with a high-efficiency multiphase flue gas treatment system, which ensures that any impurities found in the flue gases being discharged into the air are well below the emission limits specified in the environmental permit.

The plant’s emissions are strictly regulated, and nine emissions components are monitored using continuous measurements. The Regional State Administrative Agency issued an environmental permit decision on 7 May 2018 for the Korvenmäki waste-to-energy plant, and the plant operates in accordance with its terms. In 2022, the permit decision was revised to comply with the BAT conclusions. At the end of 2023, the permit amendment increased the capacity of the plant from 120 000 tonnes to 135 000 tonnes, and allowed for the treatment of some new waste fractions.

Read the terms of the environmental permit 2018 (in Finnish)

Review of the environmental permit 2022 (in Finnish)

Modification of the environmental permit 2023 (in Finnish)

Waste-to-energy plant, annual emissions 2024 (kg)

The estimated maximum WtE plant emissions fall well below the limits specified in the environmental permit.

Other environmental impacts

Carbon dioxide

The plant’s carbon dioxide emissions are no more than 50,700 tonnes a year. Half of the emissions come from district heating production and the rest from power generation. District heating emissions have been halved by replacing peat, coal and oil fuels with waste.

Carbon dioxide emissions produced in generating an equivalent amount of energy using different energy sources of energy as calculated with Statistics Finland default emission factors.

Transport

Around 20 truckloads of waste fuel are brought to Korvenmäki every weekday from the Salo and Turku regions. The same trailer combinations are used to transport the slag produced at the plant for processing.

Noise, odour and dust

The plant does not generate any additional odours or noise in the area. The waste is unloaded and stored indoors. Exhaust air from the waste bunker is not directly discharged outside: Poit is used as combustion air in the WtE plant’s boiler, thus effectively keeping odours contained. In the WtE plant’s downtime, the exhaust air is discharged outside via a filter. Trafficked outdoor areas are asphalted, and fuels, ashes and chemicals are handled, stored and transported such that there is no damage to the environment.

Ash produced by the plant

The plant’s boiler slag, boiler ash and fly ash are shipped for post-processing as their own separate fractions. The boiler slag is temporarily stored in an intermediate storage facility, from which it is collected for post-processing. Then, metals are extracted from it and sent for reuse. The mineral matter contained in the slag can be utilised for instance in earthwork. Around 99% of the bottoma slag is repurposed. The boiler ash and fly ash from flue gas treatment are neutralised and properly disposed of.